Project Complete (mostly...)!

We're finally done (mostly.....see below for the caveats). It took just over 2 months to complete, and there was at least one significant bump in the road, but the guys at Neptune Marine Electric in Ladysmith, BC did a fabulous job. The old batteries are out, the new batteries are in and securely mounted in the same area where the old ones were (the master stateroom bilge), and the battery management and other systems are beautifully installed with cables labeled and properly secured.

System Design

We removed 24 Vision CL800 batteries that provided a total of 1600 Amp-hours of capacity, though given the discharge limits of AGMs, the very best we could really expect was about 800 amp-hours of useable capacity. Given that it's really slow and inefficient to charge the AGMs beyond about 90% due to the rapidly decreasing current the batteries will accept as they charge, we really only got about 700 amp-hours of useable capacity--and that's when the batteries were healthy. In the past summer, we were operating between 95% (which required a LOT of generator run time) and about 75%, since the terminal voltage fell off precipitously after about 75% state of charge. As a result, our 1600 AH batteries, were really only yielding about 360 amp-hours. I put a lot of hours on my generator this past summer! The solar helped....but not nearly enough as we had a really gray and rainy early summer in Southeast Alaska.

By the way, it's important to note as well that this was my second set of Vision AGM batteries. I can't really complain about them. The first set that was installed at the factory lasted about 8 years before they exhibited the same limited capacity. At the time (2016), I considered switching to Lithium, but the batteries were still extremely expensive (not that they're cheap now!), and it seemed like the systems were still a ways from mature. As a result, we replaced the first set of AGMs with an identical set of Vision AGMs. We got 9 years out of those batteries--which really isn't bad, given that we spend a lot of time at anchor, so the batteries get a lot of exercise.

When the second set of AGMs were showing that they had reached the end of their useful life this summer, I decided to pull the trigger on the Lithium upgrade.

We replaced the 24 AGM batteries with six Victron NG 25.6 300 amp-hour batteries, for a total of 1800 amp-hours. However, because we can safely discharge the Lithium batteries to at least 20% (and really as low as 10% if we're willing to sacrifice a bit of life), we now have effectively at least 1400 amp-hours of useable capacity. In addition, because the Lithium batteries will accept full bulk charging all the way up to at least 90% (and often 95%+), we can run the generator for less time and under a heavier load--which will keep the generator happier.

After some discussion with Dylan and Jarad, we chose to separate the six batteries into two banks of three batteries, each managed by a separate Victron NG BMS (Battery Management System). This system is slightly more complex than just putting all the batteries in parallel and managing them with a single BMS, but it has several advantages:

- First, splitting the batteries into two banks provides some redundancy. In the event that either of the BMSs detect issues with the batteries they manage, or in the event of a BMS failure, we won't lose our entire house bank. We'll obviously have less capacity (about 900 AH, with roughly 700 usable---amount the same amount we had before with the AGMs!), but we won't be dead in the water.

- Second, splitting the bank into two halves reduces the load on each BMS. While we don't expect to ever get particularly close to the 1000-amp capacity of each BMS, splitting the load between the BMSs means that there will always be even more "margin" between the maximum specs of the BMS and our load. That's good for reliability.

- Third, each BMSs can balance the load among the three batteries in their bank, and they also communicate with each other to balance the charge and load across the banks, so the balancing is more effective than a single large parallel battery bank.

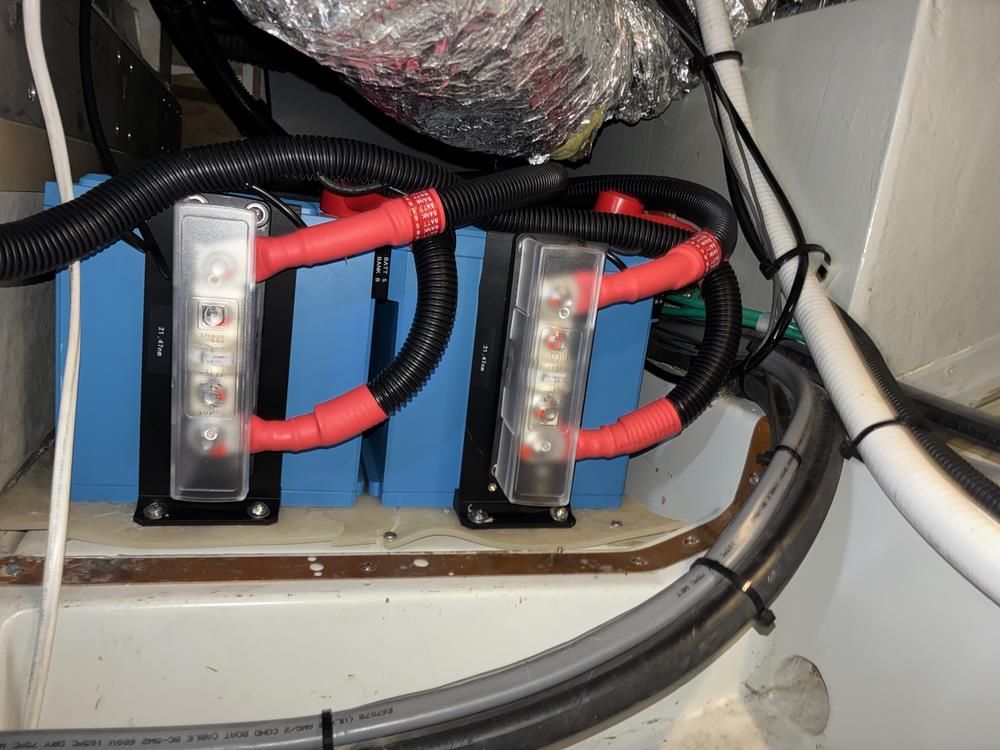

Each bank has a Lynx box that accepts the input cables from the three batteries with appropriate fuses, and combines them on a heavy built-in bus bar that ties directly to the Victron NG BMS. There's a class-T fuse mounted directly on the end of each battery to protect the cable that runs from the batteries to the Lynx box. Careful attention to fusing is very important with these batteries because their very low internal resistance means that they can generate HUGE amounts of current. That's a good thing....unless there's a fault like a short circuit. Then the enormous current capabilities of the batteries are a potential source of heat and fire, so careful fusing is critical.

The Lynx boxes and BMSs are installed in the bilge close to the batteries. The output of the BMSs goes to the electrical room and ties to the original big DC bus bar through a pair of Class-T fuses.

Keep in mind that I had already replaced the original Mastervolt Inverter-chargers that came on the boat several years ago. One of the two inverters had gone crazy and generated a brief high voltage that damaged several things on board. I removed both of the Mastervolt inverter-chargers and replaced them with a pair of Quatro 5KW inverter-chargers, so we had a bit of a head start on the conversion.

In addition, when I installed the solar panels on the hardtop and pilothouse roof a few years ago, I used a Victron MPPT controller to manage the solar, so all of the system--the new batteries and BMSs, the inverter-chargers, and the MPPT controller, all talk to each other and work together. That was one of the reasons I chose to use the Victron system, including their batteries.

The system is controlled by a a new "Ekrano" touch-screen controller. The Ekrano is essentially an upgraded Cerbo GX with the 7" touch screen display combined into one unit. The Ekrano will go in place of the older Color Control GX that I had installed when I put in the Quatro inverter-chargers. Of couse, the Ekrano display is considerably larger than the old Color Control GX, so I'm in the process of making a new panel that that had the Generator control, the Color Control GX, and the controls for the old Mastervolt chargers (which I kept....more on that in a moment). For the moment, the Ekrano is just temporarily installed hanging from it's cables as I wait for the new panel to be delivered.

A bump in the road....

Koinonia also had two large alternators--a 210-amp Balmar that is on the main engine, and a second hydraulically-driven alternator. These two alternators were controlled by a pair of Balmar regulators with a "center fielder" box between the two regulators to coordinate the two alternators so that they would share the load and work together effectively. We initially were going to just keep the Balmar regulators, as they can be programmed to have Lithium-compatible charging parameters. However, some of the new smart regulators will actually integrate with the Canbus system that connects all the Victron equipment so that the regulators can also be controlled by the Victron system. So.....we decided to replace the Balmar regulators.

And that's where the first big bump in the road happened.

We considered the two leading providers of smart regulators: the Wakespeed and the Arco Zeuss. However, a new third player in the market--called Revatek--looked very interesting as they advertised a single regulator that could handle two alternators, which seemed ideal for my setup. It was a startup company, and I asked a few questions about their financial stability and got reasonable answers. We decided to take a chance and use their product. That proved to be a mistake.

Dylan and Jarad ran a test of the alternators and, unfortunately, during that test, the Revatek regulator went crazy and drove the alternators up to a dangerously high output voltage. Fortunately, the Victron BMSs, are smart enough to protect the batteries and they opened their internal contactors. However, because the regulator didn't respond properly to the BMSs signals to stop charging, the alternators were still producing full output when the contactor opened, so a big voltage spike occurred. That voltage spike destroyed all of the LED light fixtures that were on at the time (which was about 2/3 of them). As a result, we now have a box of over 50 dead LED light fixtures!

To their credit, Jarad and Dylan stepped up and have acquired all the replacement fixtures. They would have even installed them all, but I wanted to get the boat back home, so I agreed to do the installation. That proved to be a fairly large project, just given the number of fixtures and the fact that the old dimmers that were on the boat are not compatible with the new fixtures, so we needed to replace four dimmers as well.

While there were a couple of other smaller casualties from the voltage spike, the good news is that none of the expensive electronics were affected.

In the end, we removed the Revatek regulator and went back to two Arco Zeuss regulators. which also integrate nicely with the Victron system.

What's Left to be Done

Is there such a thing as a boat project that is ever really done? This one is no exception. It's mostly done and I am looking forward to getting more experience with the new system and reaping the substantial benefits of the Lithium batteries. But there are still a few things I want to do to really complete the system:

First, is integrating the existing Mastervolt chargers (just chargers--not the old inverter-chargers) that are still installed on the boat. The boat had two Inverter-chargers (now the Victron Quatros), and two Mastervolt chargers. Fortunately, the Mastervolt chargers can be set to be Lithium compatible. What I'd like to be able to do is take advantage of the charging capability of two Quatros combined with the two existing 100-amp Mastervolt chargers. Theoretically, I could get over 400 amps of charging capability out of the four units working together--which would charge my Lithium house bank much faster and also create a reasonable load on my big 25KW generator.

The issue is that I need to setup the Mastervolt chargers so that they will be turned off by the BMSs "Allow to Charge" signal. I also want them to only run when the batteries are in bulk phase of charging--which is most of the cycle. In order to do that, I have added a little digital input module to the Mastervolt chargers so that they can accept the allow to charge signal and a relay output from the Quatros that will open when they drop out of bulk mode. That way, the Mastervolt chargers will only try to help with the charging in the bulk phase.

We have the digital input module and have setup the wiring to use it, but I still have to set up the module using some older "Master Adjust" software.

Second, I want to connect the Ekrano control to my NMEA 2000 bus so that I can get all the battery and charging data on NMEA 2000 and accessible to my Maretron monitoring system. I can see all the Victron parameter through their really nice Remote Portal anywhere via the internet, but I'd like the Maretron system to monitor and alert me as it did with the old battery system. That shouldn't be hard to do......but it's yet to be done.

What did it Cost?

Everybody wants to know......what did it cost? Well......that's not an easy answer, but hopefully this will at least give you an idea.

The first variable is the Canadian exchange rate. Today, the exchange rate is about $0.74 USD per $1 Candian dollar, but that's obviously subject to change. In most cases, the exchange rate works in the favor of a US customer.

However, there's another big advantage in having the work done in Canada. There's a paperwork process you can go through called an "E29B" that will allow you to avoid paying the Canadian GST and PST taxes (which total about 12% in British Columbia). By avoiding those taxes, and also avoiding local sales tax (which would be over 10% in Washington), you get at least a 10% advantage--even at full price parity.

Bottom line for my project, including removing the old batteries, installing the new batteries, BMSs, miles of 4/0 cable, two new Arco Zeuss regulators, the Ekrano display, and many hours of labor, the system cost roughly $50K in US dollars. Keep in mind that I'd already installed the Victron Quatros a few years earlier, so that cost isn't included here. There was also some moorage cost in Ladysmith, as the boat was there for about 2 months. The moorage was about $1K/month.

Now I just need to go cruising!

Go back to the first post in this story.